The secret to premium frames

What makes for quality eyewear? Why, dedication to fine workmanship, of course. Find out which two factors are essential for making timelessly beautiful, technically impeccable frames.

Proven production technology

It’s not enough to have an innovative idea. If you want to create top-quality frames, you need design and market practices that satisfy customers and stand the test of time. That’s why the technical know-how and manufacturing processes behind each creation are so important.

Take Blackfin, for example. In 1971, Maria Pramaor opened her frame lab and workshop in Agordo, in the Italian Alps. Twenty years later, while the rest of the industry was still selling traditional metal and acetate frames, Maria and her husband decided to go a different route: titanium. They didn’t know it then, but when they sent their technical directors to Japan to learn how to work with titanium, they were pioneering what would later become a huge share of the eyewear industry.

Blackfin offices |

Agordo (Italy) |

Image : Blackfin |

Image : Blackfin |

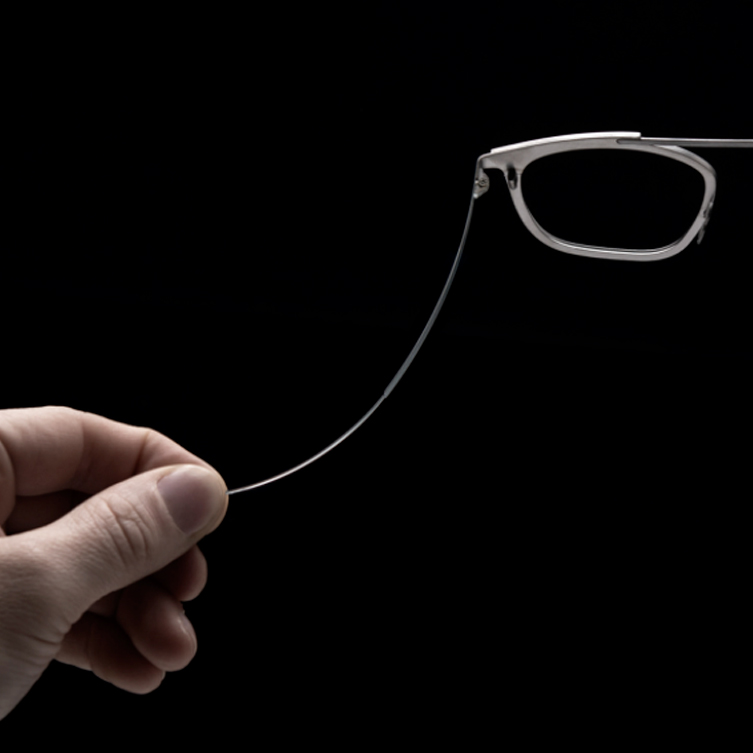

The titanium Blackfin uses to make its frames is pure, certified Japanese titanium. The material is twice as strong as aluminum and just as tough as steel—yet it weighs 40% less.

What’s more, titanium and beta-titanium (which is even more flexible than pure titanium) won’t cause allergies or irritation because they have no nickel or other heavy metals in them.

More than a production process—a ritual

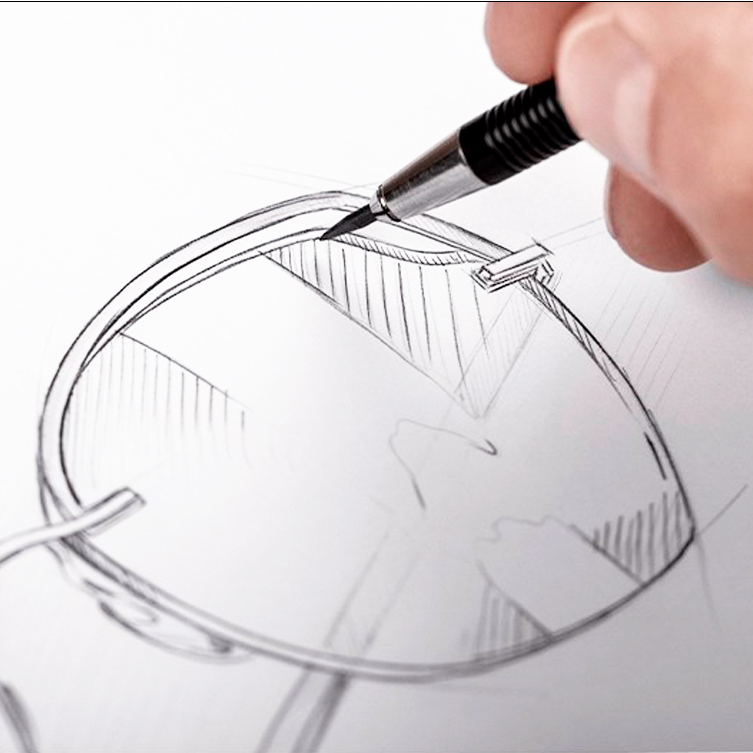

Blackfin frames are designed with dedication and attention to detail. From initial concept to sketch to prototype, hundreds of colour-matching experiments, technical tests, and adjustments are required.

Blackfin is perhaps most famous for its incredibly flexible temples and the beta-titanium bridge that can be easily adjusted to suit any face shape. And its innovative Swordfish temple tips give you control over the length of the temples.

Image: Blackfin |

Image: Blackfin |

Speaking of innovation, Blackfin also pioneered the use of high-precision anodic laser engraving and the Blackfin Nano-platingTM process. The process works on a molecular level to create striking, totally original colour effects.

|

|

|

Blackfin’s creative process is about more than just rigorous production. Each pair of glasses is the culmination of a series of rituals in the great Italian tradition, and bears the imprint of the artistic talent of every person involved in creating Blackfin frames for more than 50 years.

What it means to be neomadeinitaly

Today Blackfin holds a unique position in the market, not only because of its renowned expertise in working titanium but also due to the quality of its workmanship. Blackfin frames aren’t Made in Italy, they’re neomadeinitaly. That means that every step from start to finish is completed in Italy, ensuring an unsurpassed level of excellence as well as production techniques that are optimized for social responsibility and sustainability.

Silhouette slays with precision quality

Another key to a product’s success is uncompromising quality control. And that’s what you get with Silhouette’s rimless, half-rim, and full-rim glasses, created in Austria since 1964. Silhouette’s Austrian craftsmanship, titanium expertise, and groundbreaking designs have made it a leader in innovative, lightweight eyewear.

|

Half-rim and full-rim models |

The secret to Silhouette’s success lies in its extremely high standards of workmanship and its use of high-tech materials like titanium and the brand’s patented SPX and SPXng plastic.

Frames may go through a hundred quality control steps before they’re finalized. Workers pore over every detail to ensure each product delivers flawless strength, style, comfort, and fit.

It’s the kind of precision that gave birth to the now-iconic Titan Minimal Art (TMA) in 1999. Weighing in at less than 1.8 grams, with no hinges or hardware, TMA is Silhouette’s lightest model.

Image: Silhouette (Titan minimal Art) |

|

Image: Silhouette |

The company has really made its mark on the industry. On top of its innovative SPX plastic (Silhouette + Polymer + secret ingredient X), Silhouette also developed a maintenance-free Snap-Hinge technology and a unique colour process for its lightweight frames.

The end result: unique, thoughtfully designed eyewear

Another feature of fine eyewear design is customization. Blackfin and Silhouette are two good examples of brands with production techniques that let you customize your look.

Blackfin’s use of laser etching (instead of traditional printing), choice of colours, and option to put your name or initials on your glasses are key. As for Silhouette, since their glasses are made from start to finish at the company’s headquarters in Austria, your colour, shape, and design options are virtually endless.

Image: Blackfin (custom engraving) |

Image: Silhouette (Elegance collection) |

Whether we’re talking about flashy high-tech Blackfin frames or featherlight Silhouette rimless glasses, both eyewear makers agree on one thing: style should never come at the expense of comfort or durability.

Ultimately a unique, thoughtfully designed product is a success if the wearer never wants to go back once they’ve tried it.

When your eyewear has timeless appeal and impeccable technical workmanship, well, that’s quality.

Contact your local clinic to find out if it carries Blackfin and Silhouette frames.

- Eyewear Specialist

- Frames

- Technology